EMI copper mesh

EMI copper mesh

EMI copper (sleeve) mesh is a flexible conductive sleeve of tinned copper wire. When winding with tension the sleeve is compressed, which ensures adherence to all profiles without wrinkling.

It is used for shielding cable connections, restore of power cables screen, align of the electric potential, as well as to align of the joint area in the oil-filled cables. It is also widely used as part of mid-voltage and high-voltage cable joints (copper mesh tape, braided copper shield).

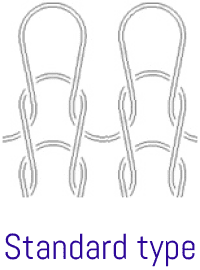

A monofilament or polifilament mesh of one material in all of vertical and horizontal rows.

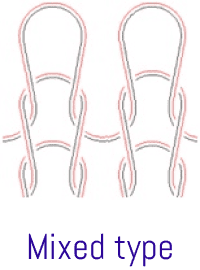

A mesh of combined polifilaments of the materials of various properties in all vertical and horizontal rows.

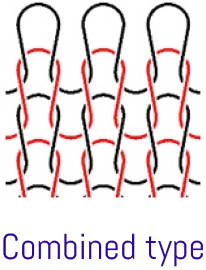

A mesh of the combined filaments of a same material by property, where the threads alternate in horizontal rows.

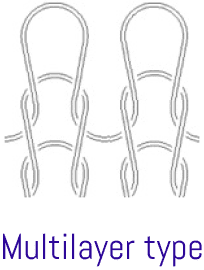

A mesh with two or more layers, where each layer is located inside the other and may represent by itself standard, mixed or combined type.

Types of EMI copper mesh

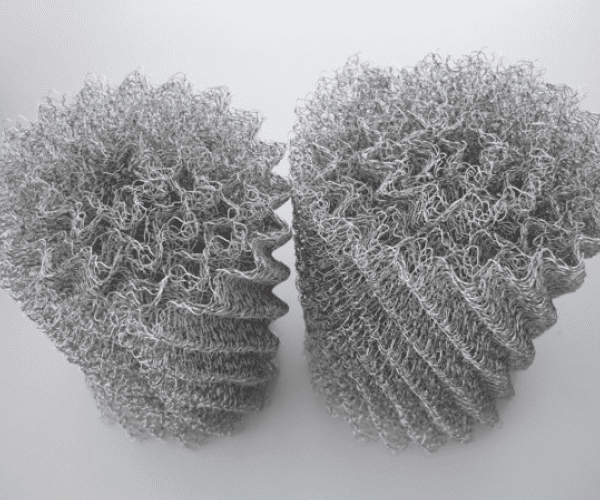

The mesh can be used both in its original form or be processed into flat ribbons, stacked in layers, curled, crimped, pressed or processed by a combination of the foregoing.

Mesh crimping is often used. The process is characterized by passing mesh through special rollers to obtain the diagonal (herringbone) corrugations or fluting. This gives mesh an additional depth, typically between 4 and 8 mm.

If you have any questions or ready to place an order, please contact our specialists for more information.

Application of EMI copper mesh

Screening mesh provides an ideal solution for many applications, especially when you need to repair leaks in the electronic equipment housings, shielding of the electrical and electronic cables, grounding, protection against static electricity and so on.

The screening can be made in different versions: as a sleeve for easy installation, for extrusion of cable wires, as well as by bars, rods, ribbon, etc.